scpmkj@gmail.com

Get A Free Quote

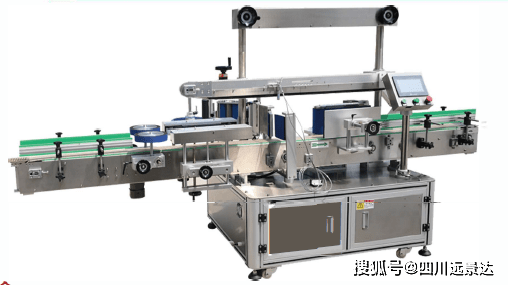

The fully automatic double-sided labeling machine is a multifunctional labeling machine suitable for double-sided or single-sided labeling of square or flat products. It has the characteristics of simple adjustment and wide application range. It only requires a small amount of adjustments to complete the conversion of various specification objects. The layout of the labeling station is simple and reasonable, high-speed and stable. The double pressure roller structure ensures the tension of the label and avoids the phenomenon of label breakage caused by die cutting damage of the base paper. A segmented clutch provides more balanced tension. An advanced and friendly independent man-machine interface is adopted for control, and operating parameters can be stored and recalled. The man-machine interface displays any abnormalities and guides troubleshooting. Easy to operate, anyone can easily operate and use this equipment quickly.

The labeling workflow of the fully automatic double-sided labeling machine is as follows: the product is manually loaded (or conveyed by the upstream conveyor belt)→ conveyed by the plate chain conveyor belt → material distribution → the shaping mechanism corrects the shape of the product → the pressing belt is pressed → electric eye detection → The label feeder mechanism receives the electric eye signal and delivers the label → the label is quickly delivered to the part of the product that needs to be labeled → labeling → pressing → the finished product is output through the plate chain conveyor belt.

Debugging steps for fully automatic double-sided labeling machine.

The adjustment steps for the fully automatic double-sided labeling machine are as follows:

1. Adjustment of belt pressing mechanism

Adjust the height of the pressing belt to be 3mm lower than the product to be pasted.

2. Adjustment of the plastic organization

The forming belt is centered on the pressing belt. The width of the pressing belt is just enough to hold the bottle opening, and the height is adjusted to the center of gravity of the workpiece.

3. Adjust the electric eye of the measurement object

For square products, the vertical angular distance between the electric eyes is approximately 3 mm.

For arc-shaped products, the tangential distance between the electric eye and the angle is approximately 3 mm.

4. Adjustment of title

Adjust the angle of the mark head to form a cutting angle with the workpiece to be pasted, the distance is 3-5 mm, and the mark plate is perpendicular and parallel to the workpiece to be pasted.

5. double head adjustment

Align the front and back sides with the opposite sides of the target plate, as described above.

6. bid testing

The standard length is 2-5 mm longer than the standard plate, and the deviation of the stop position for each test shall not exceed 0.2 mm.

7. Adjust the side guardrails so that the bottles are transported to the centrally located forming mechanism.

8. Try labeling.

The above adjustment steps are based on the actual labeling effect.