scpmkj@gmail.com

Get A Free Quote

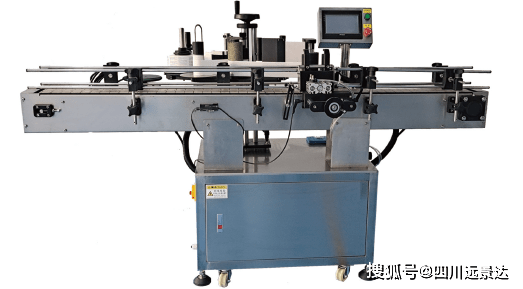

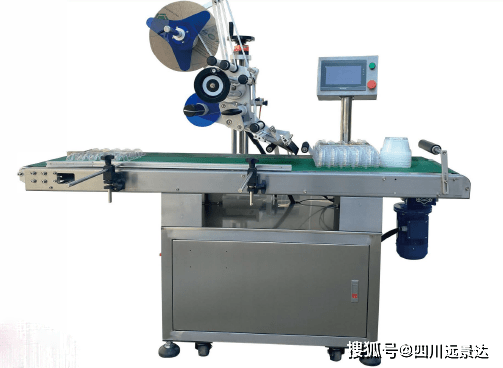

Labelling machines have been widely used, and with the rapid development of labeling technology, the competition for fully automatic labeling machines in the market has become increasingly fierce, from manual labeling to semi-automated labeling. The fully automatic labeling machine has accurate position, good quality, high stability and high efficiency. It avoids a series of problems such as low manual labeling efficiency, skew sticking, and uneven glue thickness, effectively reduces the waste of slurry and reduces labeling. Labor costs.

Working principle of fully automatic labeling machine:

1. The working process of the fully automatic labeling machine starts with the packaging box being transported to the labeling machine on a conveyor belt at a constant speed. A mechanical system of a labeling machine includes a driving wheel, a labeling wheel and a reel. The drive wheel intermittently drags the label tape as it is from the reel and through the label wheel, pressing it against the box. The roller adopts open-loop displacement control to maintain the tension of the label tape. Since the labels are closely connected, the labels must be constantly opened/closed.

2. A box where the label and the label wheel move at the same speed. When the belt reaches the designated position, the driving wheel of the label belt accelerates to a speed that matches the belt, and label application slows down and stops.

3. Since the label can be slid, it has a registration mark to ensure each is in the correct position. The sensor reads the registration mark, and during the deceleration phase of the label strip, the drive wheel is repositioned to correct any incorrect position of the label strip.

4. Another way of saying it is: after the bottles enter the automatic labeling machine, the bottle star wheel stops opening until the number of bottles reaches a certain level, and the bottles are pushed forward by the conveyor belt. After entering the bottles, they enter the bottle spacing star wheel through the bottle screws, and then press the bottle head presses the bottle. Under the action of the cam, the bottle moves downward and reaches the first station.

5. At the same time, the air cylinder pushes, and after the pattern plate and rubber roller are glued, the drum clamps the bottle, cuts the paper, and attaches the paper to the bottle. After the labeling machine is at a certain angle, the label machine rotates 90 degrees clockwise at the same time under the action of the cam. After brushing the bottle area, the paper includes a brush so that the bottle cap can be slipped out by the brush. The paper supports the bottle on the track and is rotated clockwise and counterclockwise multiple times. When transferred to the second stop labeling position, it is tangent to the clamping drum on the back of the bottle. At this time, label the label back, and then rotate it through the supporting plate to brush the back label paper flat with a brush.