scpmkj@gmail.com

Get A Free Quote

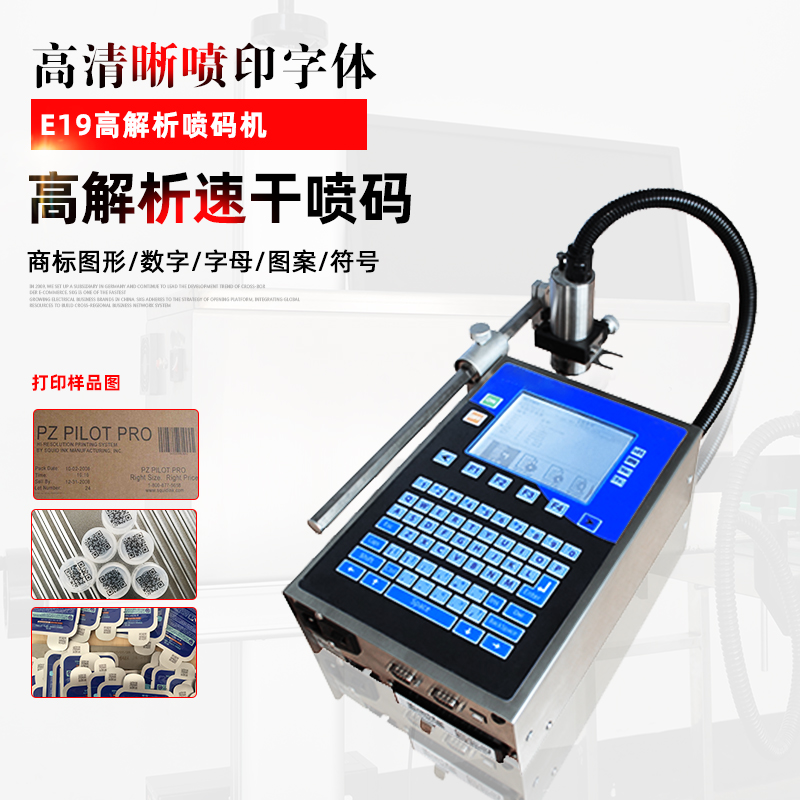

One of the principles of the inkjet printer is that it can enable the inkjet printer to continuously spray code while working. The most important reason for continuous inkjet printing is that the ink must be continuous. The handheld inkjet printer is also called a portable inkjet printer. It can be carried around with you to print and is light and simple to operate. Hand-held inkjet printers are different from small character inkjet printers, large character inkjet printers, high-resolution inkjet printers, and laser inkjet printers. They are suitable for enterprises that do not have high production speed requirements. Hand-held inkjet printers require a certain size to print products, with multiple fonts such as solid, dot matrix, hollow and colorful colors. Of course, only when the ink can be continuous can the inkjet printer's inkjet printing effect be continuous. If there is a period of time when the ink is sprayed, the supply of ink will lag, such a time, even if it is only a few milliseconds. Maybe there will be an obvious fault in the inkjet effect. As shown in the picture:

Because the work efficiency of the inkjet printer is relatively high. Ink sprayed every second can form a long barcode on a product or device. In this situation. Even when coding, there is only a little time for gas to enter during the coding process. The entry of gas for a short period of time may not cause a large cross-section, so in terms of the supply of ink, the control of the entire inkjet machine is very precise.

The entire process of ink passes through the initial uncharged ink under corresponding pressure conditions. If the inkjet printer has a 7-point nozzle, there will be 7 independent valves to control the printing of large fonts. It is generally used on outer boxes, outer packaging or large workpieces, such as thick water pipes or asbestos boards, Heat insulation boards and other workpieces. Since the 1970s, Matthews Swedot branch developed the world's first large character inkjet printer, its product has maintained its first position in the global large character inkjet printer market. Worldwide, more than 500,000 large-character printer nozzles have been successfully installed and debugged for customers. Its 8000 series products can print up to 5 rows at a time with a single nozzle, with a running speed of 240 meters/min. In controlling the overall viscosity of its ink, we use what we commonly call viscosity. Only with the corresponding viscosity of the ink jet can we accurately spray the ink to the designated place. The next step of processing is underway. Therefore, this process must control the pressure and ink viscosity. This can ensure the continuity of the entire inkjet process. In other words, it is only good at this beginning of inkjet. Only then can the entire working process of the inkjet printer proceed smoothly.

After the ink is ejected. The entire ink is ejected through the nozzle. At this time, due to pressure and adhesion to the nozzle. This allows continuous ink to form a very uniform ink space when it leaves the nozzle. Such a slender ink space. There are many small ink particles in the middle. Under high-speed movement, the ink space can be injected into the charging area below very quickly. Small particles of ink after passing through the charging area. In our opinion, with small ink that can be used to write fonts on the equipment, and with charged ink, the inkjet printer can maintain adhesion performance on the equipment for a long time. Only in this way can it be maintained for a long time. Through the process of adding electric charges, the ink particles have already charged as they pass by, so that the ink particles can separate the corresponding ink particles during the process of the charging electrode below.

Therefore, the characteristics of the voltage are an effective separator for these small ink particles, so that the ink can be effectively separated, and the separated ink will not be thrown away. Instead, a further additional charge is carried out, and the additional charge is passed through the other electrode. We can say that the following separation ink applies a negative charge. The inkjet printer forms two groups of ink particles through the application of negative charges. Then there is a processing method for our team ink, which changes the set electrode voltage. This allows us to spray ink line particles out in the final ejection port in the shape and method we need, and then form the code on the equipment or appliance. The effect of electric charges can persist on the device for a very long time.

At the same time, some unused ink in the inkjet printer will be recycled in a corresponding way. A certain voltage is applied to the charging electrode of the Anhui inkjet printer. When the ink droplet is separated from the conductive ink line, it will instantly carry a negative charge that is proportional to the voltage applied by the charging electrode. By changing the voltage frequency of the charging electrode to be the same as the frequency at which ink drops break, each ink drop can be charged with a predetermined negative charge. Under the continuous pressure, the ink flow continues to move downward and passes between two deflection plates with positive and negative voltages respectively. The charged ink drops will deflect when passing through the deflection plates. The degree of deflection depends on the amount of charge they carry. Uncharged ink drops will not deflect and will fly downward and flow into the recovery tube. Finally, it is returned to the ink tank for recycling through the recycling pipe. The charged and deflected ink drops fall at a certain speed and angle onto objects passing in front of the vertical nozzle head. Convenient for the following recycling.