scpmkj@gmail.com

Get A Free Quote

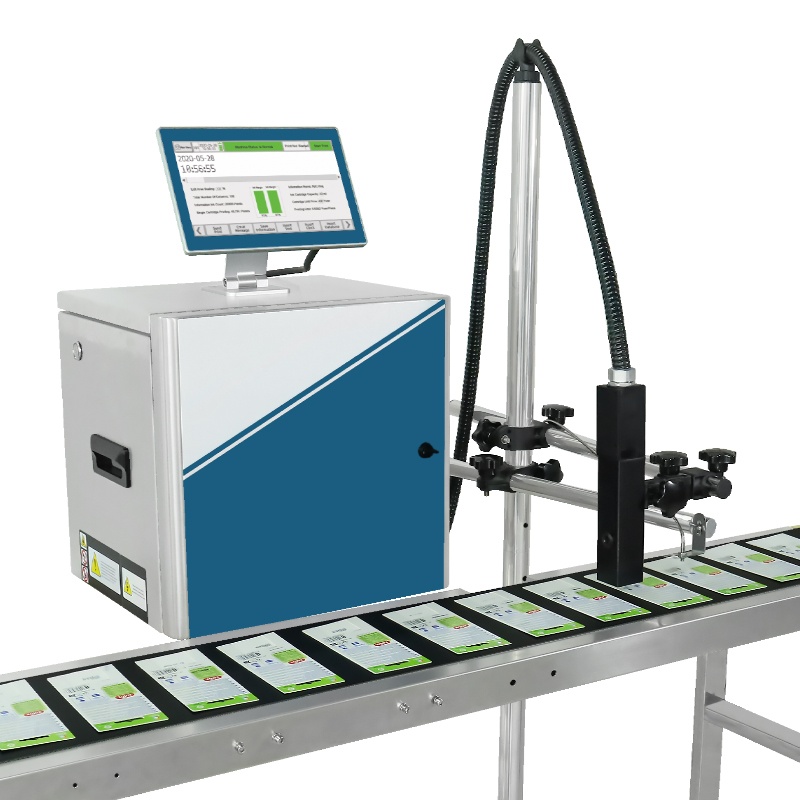

In industrial production, inkjet coding machines are widely used for product labeling. However, when applying inkjet coding to curved surfaces, deformation issues often occur. This not only affects product appearance but may also compromise functions such as traceability and anti-counterfeiting capabilities. The same applies to products manufactured by Shicai Inkjet Coding Machine Co., Ltd. Below, we will analyze the causes of surface deformation during inkjet coding on curved surfaces from aspects including machine characteristics, surface properties, production environment, and operational settings.

1. Characteristics of inkjet printer itself

The distance and angle control between the nozzle and the curved surface is difficult

Standard inkjet printing equipment is typically designed for flat products. When handling curved surfaces, maintaining consistent distance and angle between the nozzle and print surface proves challenging. For instance, in narrow-diameter hoses where the printing space is confined, operators must constantly adjust the nozzle position to ensure proper inkjetting. However, real-world applications reveal that the dynamic curvature of curved surfaces causes the distance and angle between the nozzle and surface to fluctuate continuously. This results in unpredictable droplet positioning and angles during inkjetting, ultimately causing printed patterns to deform.

The precision and flexibility of inkjet printing are limited

Different material types of hose pipes require varying precision and flexibility from inkjet coding equipment. Plastic tubes with smooth surfaces struggle to adhere conventional inks, while rubber hoses' elasticity often causes misalignment during printing due to deformation. Certain metal tubes treated with special surface treatments may not yield clear or durable markings through standard processes. When handling these curved materials, inkjet machines might fail to maintain required accuracy and adaptability, resulting in distorted printed patterns.

Curvature characteristics

The surface shape is complex

Curved surfaces come in various forms, ranging from regular cylindrical and conical shapes to irregular surfaces. The complexity of these curved configurations makes predicting droplet diffusion and adhesion patterns after inkjet printing particularly challenging. For instance, on surfaces with high curvature, ink droplets may shift due to gravitational forces and surface tension, resulting in distorted printed codes.

Curved surface material differences

Curves made of different materials have distinct physical and chemical properties. Plastic surfaces may exhibit poor ink adhesion, resulting in blurred or distorted printing. Metal surfaces can generate reflections that interfere with the printer's recognition and positioning, leading to inaccurate marking positions.

III. Production environmental factors

Temperature and humidity effects

Temperature and humidity fluctuations significantly impact ink performance and inkjet printer operation. Excessive heat may cause rapid ink evaporation, altering droplet velocity and trajectory. Overly high humidity can lead to ink condensation at the nozzle, compromising print quality. During curved surface printing, these environmental variables further exacerbate deformation during the process.

Dust and foreign matter interference

Dust and foreign matter may exist in the production environment, which may be attached to the curved surface or nozzle. The existence of dust and foreign matter will affect the normal ejection and attachment of ink droplets, resulting in problems such as breakpoint, blur or deformation of the printing code.

IV. Operational setting factors

The inkjet parameters are not set properly

The parameters of inkjet printers, including printing speed, spray height, and distance, should be adjusted according to actual production requirements. When performing curved surface printing, improper parameter settings may cause deformation. For example, excessive printing speed might result in ink droplets failing to adhere accurately to the curved surface, while overly high or low spray heights could affect both the ejection angle and diffusion range of the ink droplets.

Lack of targeted debugging

For curved surface inkjet, the inkjet machine usually needs targeted debugging and optimization. However, in actual production, operators may lack relevant experience and skills, and do not fully debug the inkjet machine, resulting in the deformation problem of inkjet can not be effectively solved.

sum up

The deformation of curved surface coding by inkjet printer manufacturers stems from multiple contributing factors. The equipment's inherent limitations in precision and flexibility when handling curved surfaces, combined with the complex geometries and material variations of surfaces, significantly increase coding difficulty. Environmental factors like temperature, humidity, and dust in production settings further compromise coding quality, while improper operational configurations directly cause deformation issues. To address this challenge, manufacturers must continuously upgrade inkjet technology to enhance curved surface compatibility. Operators should also optimize equipment adjustments by configuring appropriate coding parameters for different surfaces and materials, ensuring consistent production quality.