scpmkj@gmail.com

Get A Free Quote

In the food industry, inkjet printers are key equipment for ensuring product compliance, traceability, and safety. Their application scenarios closely revolve around regulatory requirements and market demand in food production, mainly reflected in the following aspects:

1. Mandatory identification of core information

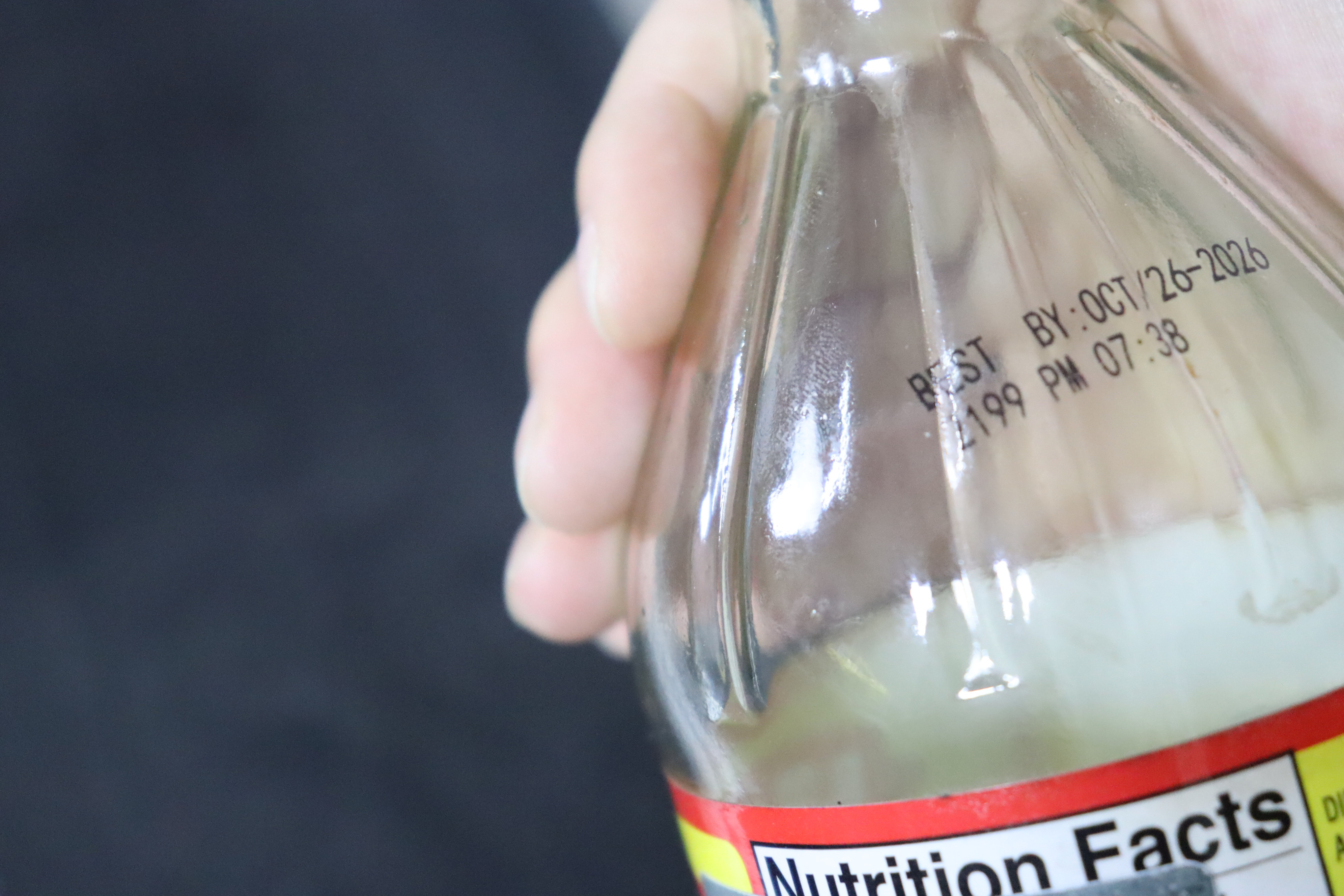

-Production date and shelf life: Clearly print the production date, shelf life or best before date on food packaging (bagged, bottled, canned, box body, etc.), which is a mandatory requirement of food safety regulations in various countries to ensure consumers' right to know.

-Production batch number and batch: Spray print unique batch codes to facilitate enterprises to track the production time, production line, raw material source, etc. of products in the same batch. Once quality problems occur, they can be quickly located and recalled.

2. Anti counterfeiting and traceability management

-By printing QR codes, barcodes or traceability codes, consumers can scan the codes to view information about the production process, inspection reports, circulation links and other aspects of the product. Enterprises can monitor the flow of products through the system to prevent counterfeiting and smuggling.

3. Adapt to the characteristics of food packaging

-For the diverse materials of food packaging (plastic, paper, metal, glass, film, etc.), as well as the low temperature and humid environment of some products (such as refrigerated food), the inkjet printer needs to have anti pollution, friction resistance, and adaptability to low temperatures to ensure long-term clear labeling.

4. Segmented scenario applications

-Bulk food: Print weight, unit price, total price and other information on the weighed packaging.

-Beverage industry: Stable spray printing on curved or irregular packaging such as bottle bodies and caps, suitable for high-speed production lines.

-Baking/Fresh: For products with short shelf life, the inkjet printer needs to support quick information replacement to meet the production needs of small and multiple batches.

The efficient and precise printing capability of inkjet printers helps food companies meet strict regulatory requirements while improving product traceability efficiency, making it an important link in the food safety production chain.