scpmkj@gmail.com

Get A Free Quote

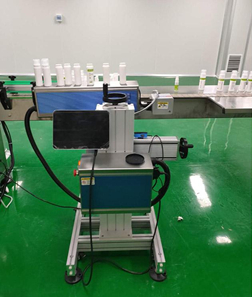

Laser coding technology is a more advanced technology than ink coding technology. The application of laser inkjet printers in the China market has just begun, but the development trend is rapid. Laser inkjet printers greatly improve the problems existing in traditional coders, improve the reliability and flexibility of the equipment, and are suitable for various metallic and non-metallic materials.

Laser marking machines are laser marking machines. They use different lasers to apply laser beams on the surfaces of various materials, and use light energy to physically or chemically change the surface materials, thereby carving patterns, trademarks, characters and other permanent marking equipment.

Common laser marking machines include: fiber laser marking machines, carbon dioxide laser marking machines, and ultraviolet laser marking machines. The main ink printers include: small character inkjet printers, UV inkjet printers, thermal foaming inkjet printers, etc.

The main differences between laser inkjet printers and ink inkjet printers are as follows:

1. The biggest difference between laser inkjet printers and ink inkjet printers is that they have no consumables, while ink inkjet printers require the use of ink to print content.

2. The laser inkjet printer can perform shallow metal engraving, and it uses high-energy laser energy to permanently mark various metal and non-metal surfaces. The marking effect is corrosion resistant and prevents malicious tampering.

3. The definition of code coding is different. The definition of laser code coding is higher than that of small character code coding machines, but lower than that of high resolution code coding machines.

4. In terms of anti-tamper, laser coding technology has obvious advantages, but in terms of printing speed, ink coding technology has faster advantages.

5. In terms of service life, if the ink jet machine is not cleaned frequently, the service life of the machine will be easily affected, the failure rate will be relatively high, and the life will be short. If the laser printer is properly maintained, it can be used for a long time, with a long life and a working time of tens of thousands of hours.

6. The ink printer adopts non-contact coding, which does not need to directly contact the surface of the object to be printed, and will not damage the surface or interior of the object to be printed.

7. In terms of application fields, laser inkjet printers are more widely used, but high-resolution ink inkjet printers have fast printing speed and high efficiency, making them the first choice for identification equipment for companies with large production volume.

8. The laser inkjet printer can print a large amount of data in a very small range. The laser can mark the product material itself with a very thin beam. The printing accuracy is extremely high, the control is accurate, and the printed content is clearly and perfectly interpreted. It is extremely competitive in the market, environmentally friendly and safe, without any corrosiveness, completely isolates chemical pollution, and is also a kind of considerate protection for the operator, ensuring the cleanliness and cleanliness of the production site, reducing later investment, and reducing noise pollution.

From the above, we can conclude that laser inkjet printers have unique advantages in products that require fine coding. In the future, ink inkjet printers may gradually be replaced by laser inkjet printers, but now ink inkjet printers are still irreplaceable.