scpmkj@gmail.com

Get A Free Quote

Dairy products have always been popular with consumers, and it is expected that the use of aseptic packaging for dairy products, including new and improved consumer-friendly packaging, will continue to grow at a rate of 12% by 2026.

According to the regulations, all products sold outside the factory must be attached with clear and easily identifiable product batch and production date marks in the smallest sales unit, not only to protect the legitimate rights and interests of consumers, but also to enable manufacturers to respond quickly and recall products in an orderly manner in case of emergencies.

01 Dairy production date High quality coding problems to be solved

The difficulties faced by dairy manufacturers in printing product labels generally include the following aspects:

print speed

Dairy products have a short shelf life, and slow printing speed will not only affect the production progress, but also affect the quality of dairy products and lose corporate benefits. Therefore, normal running time is critical to dairy production. Having a coding and marking speed that matches the production line is the first point that dairy producers need to pay attention to when selecting coding equipment.

Printing environment

Since dairy products usually need to be refrigerated and fresh, there are often changes in temperature and humidity in the production environment. This requires the printer equipment selected by the manufacturer to operate normally in a humid environment, and the quality of the code printing is not affected by moisture in the production environment.

Printing flexibility

The location of dairy product coding will also vary depending on the product packaging and material. For example, the coding logo of bottled dairy products is generally on the side of the bottle or bottle cap, and the logo of boxed dairy products is on the removable plastic lid. Some manufacturers also ensure that visual design will choose to spray print the logo on the bottom of dairy products containers. The coding equipment that can spray print from different directions can bring great convenience to dairy producers.

02 Agile logo laser inkjet printer logo advantages

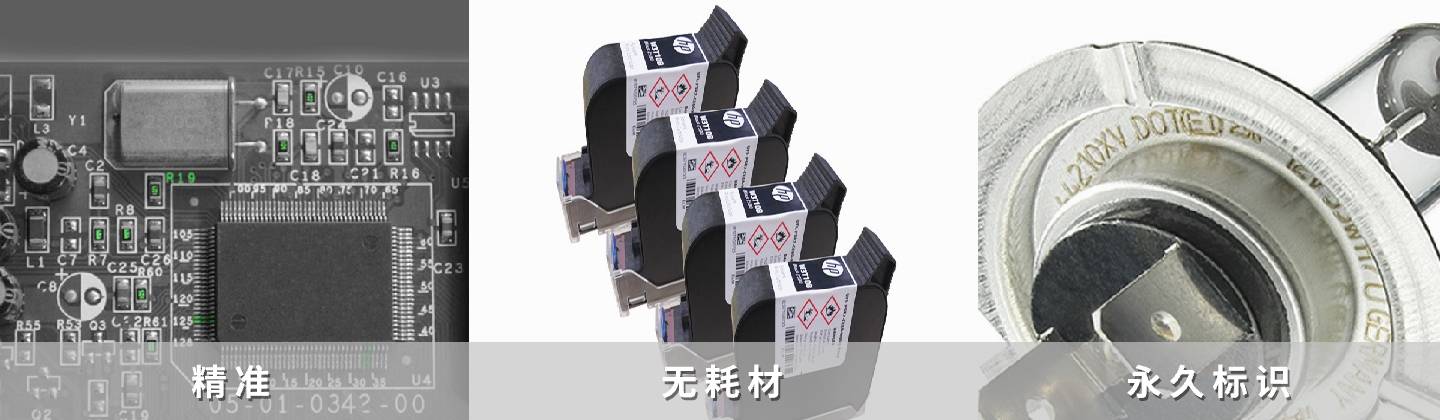

Compared with traditional ink-based inkjet printers, laser inkjet printers can obviously better perform clean and clear product coding on aseptic packaging of dairy products, protect brand image and ensure product quality.

As a leading manufacturer in the inkjet printer industry, Agile Logo has been deeply involved in the inkjet printer industry for decades and has a lot of say in laser inkjet printers. Agile Logo laser inkjet printers are worthy of the choice of dairy manufacturers.

① No need for ink, operating efficiency is not affected by the environment

When traditional ink printers assign codes to dairy products, moisture in the humid dairy production environment is easily absorbed into the ink system, which affects the stability of the ink, which may lead to clogging of the printer nozzle or other failures., and will cause certain damage to both the printing quality and the printer.

The agile logo laser inkjet printer series does not require ink and has a higher tolerance for the production environment. There is no need to worry about the problems encountered by the above-mentioned ink inkjet printer, and production efficiency will not be reduced due to external environmental factors, which will affect the overall benefits of the company.

At the same time, laser inkjet printers prevent dairy products from being contaminated by possible ink splashes during the production process. They are a good helper for sterile packaging and labeling and can effectively keep the factory environment clean.

② Permanent identification, laser machine assigned code is clear and easy to identify

Laser marking burns the surface materials of dairy packaging by laser to form a permanent mark, and does not face the problem of possible wiping off like traditional ink markings.

However, some people may think that lasers can damage package integrity, but in fact, the key to using laser coders on sterile dairy packaging is to establish a specific laser configuration composed of the optimal focal length, laser coders power, wavelength and laser coders spot diameter to allow correct marking while maintaining package integrity.

③ Flexible spray printing to meet various needs of manufacturers

The agile marking series laser inkjet printer can permanently mark different packaging materials, prevent tampering with the identification information, and mark products in various directions. It can be printed on the top, side and bottom, achieving simple production line integration.

The agile logo laser printer adopts a detachable bracket design for easy storage, ensuring smooth integration into the company's production line and is highly flexible. If there is a change of production sites, it can also easily respond to situations such as making it convenient for the company's production.

03 proofing reference