scpmkj@gmail.com

Get A Free Quote

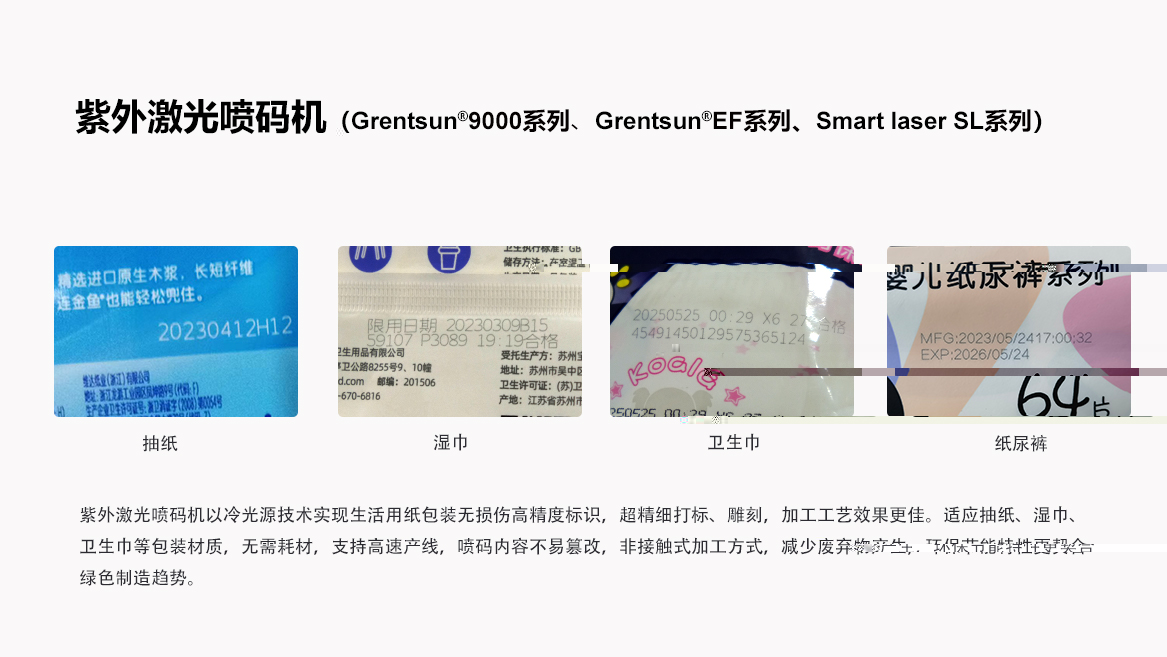

In the hygiene products industry, the accuracy, safety and durability of packaging labeling are directly related to product quality and brand trust. Due to its "cold processing" characteristics, durable marking capabilities and zero consumables advantages, the ultraviolet laser inkjet printer has become the only preferred solution for marking upgrade in the sanitary product industry. So how do Weipin companies scientifically select ultraviolet laser inkjet printers?

1. Technical principles: Why did ultraviolet laser become the "answer" to sanitary logos?

Weipin packaging materials are mainly ultra-thin composite films (such as PE, PP, PET), and their thickness is usually between 50-100μm. They are sensitive to heat and easily damaged by external force. The ultraviolet laser inkjet printer achieves marking through the "photochemical action" of 355nm short-wavelength ultraviolet light, and its technical characteristics perfectly match the needs of the sanitary product industry:

1. Physical basis for lossless marking

After the ultraviolet laser energy is absorbed by the surface layer of the material (0.01-0.1mm), it directly breaks the molecular bonds to form a mark, rather than through thermal melting or ablation. Experimental data shows that at a production line speed of 300m/min, the heat-affected zone (HAZ) of ultraviolet laser on 50μm PE film is less than 5μm, and the pass rate of airtightness test is 100%, completely solving the problem of packaging leakage caused by ink coding.

2. Environmental protection advantages of zero chemical pollution

Abandon chemical consumables such as inks and solvents to eliminate the risk of VOC emissions. After a sanitary napkin company introduced ultraviolet laser equipment, the VOC concentration in the workshop dropped from 0.8mg/m³ to 0.02mg/m³. It directly passed FDA and EU REACH certification, saving more than 2 million yuan in annual consumables costs.

3 Industrial realization of ultra-fine marking

The diameter of the focusing spot is ≤15μm, which can realize 0.05mm line width marking, meeting the high-precision spray printing of complex information such as dynamic QR codes and micro LOGO.

In the sanitary product industry, the safety of product labeling is directly related to consumer health and brand trust. Leading companies such as Vinda, Jierou, Kexinrou, and Sibao have always strictly controlled production details with high standards. With its ultraviolet laser coding technology, Wuhan Jiruixiang Industrial Systems Co., Ltd. has become a leader in these industries to improve the safety of logos."Key partner".

From Vinda's high-speed production lines to Sibao's flexible packaging, Ji Ruixiang works side by side with leading companies with customized solutions and uses its technical strength to protect the bottom line of product safety. This cooperation is not only an upgrade of labeling technology, but also a fulfillment of the sanitary product industry's commitment to consumers-to protect healthy life with reliable labeling.

From technical principles to scene implementation, the ultraviolet laser inkjet printer has become the only optimal solution for the logo upgrade of the sanitary product industry with its core advantages of non-destructive, environmentally friendly, accurate and efficient. When selecting models, enterprises need to focus on the three core parameters of laser power, optical system, and dynamic adaptation capabilities, and customize the configuration based on scene factors such as production line speed, packaging materials, and anti-counterfeiting requirements. Identification is no longer just an auxiliary process in the production process, but an indispensable part of the personal care and hygiene industry's transition from "batch management" to "full-link tracking".