scpmkj@gmail.com

Get A Free Quote

The intelligent visual inspection system for assembly lines is widely used in factories and enterprises. It is a highly automated visual inspection equipment that uses machine vision technology to detect products on the production line in real time and online to ensure product quality, safety and reliability.

Machine vision inspection systems have become a key technology and equipment to achieve product quality control on factory production lines. From the application of automation technology decades ago to the present, the development of machine vision inspection technology has always maintained a rapid growth pace. Due to the use of machine vision inspection technology, the efficiency of defect inspection in production has been improved, and the accuracy of production line inspection equipment has been greatly improved. At the same time, it can effectively reduce the company's manufacturing costs, improve production efficiency, and improve production quality.

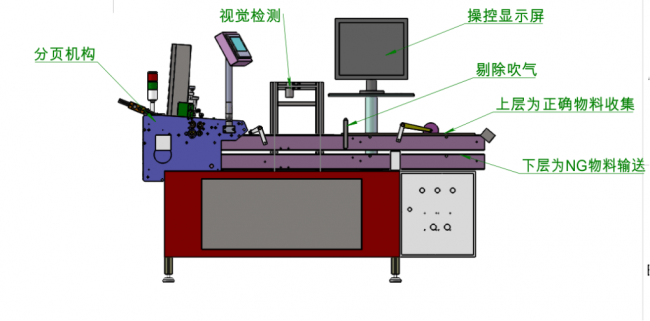

The assembly line intelligent vision inspection system is a machine vision technology that can be applied to product inspection on the assembly line. It can perform color analysis, shape analysis, edge analysis, etc., and can find detailed defects on the product surface, thereby ensuring product quality. Reliability, and at the same time, it can pick out unqualified products, thereby saving costs and improving the overall quality of products. The assembly line vision inspection system can be combined with equipment such as robotic arms, vibration plates, conveyor belts, software technology and specific lighting systems to achieve automated inspection.

Assembly line vision inspection systems have many advantages, such as reducing costs, improving efficiency, and improving accuracy and reliability. It can use technical models to find specific and negligible defects, and an identification mechanism can accurately identify products with complex shapes, even internal parts under ultra-fine size. Its efficient data processing capabilities can quickly analyze image streams and classify them into many different products, which allows it to detect abnormal items and improve product quality.

Assembly line machine vision inspection technology is becoming more and more widely used in factory production lines, playing an important supporting role in ensuring product quality. It has the advantages of accuracy, high efficiency, and low cost, and can achieve accurate and rapid detection within time. In addition, machine vision technology has the characteristics of reliability, safety, practicality and sustainability, making it an increasingly popular technology. In the future, intelligent inspection production lines with machine vision technology as the core will be widely used in the production lines of factories and enterprises.

In the automotive manufacturing industry, assembly-line intelligent vision inspection systems can be used to inspect the size, appearance and assembly quality of automotive parts. These inspections include the diameter, profile and screw hole locations of the wheel hub, as well as critical components of the engine, brake system and transmission system. By carrying out high-precision image processing and analysis of these parts and components, substandard products can be discovered and eliminated in a timely manner to ensure the quality and safety of the car.

In addition, assembly line intelligent vision inspection systems are also used in the electronic product manufacturing industry. This system can be used to test the assembly quality and functional performance of electronic products, including whether the components on the circuit board are correctly installed, whether the soldering is firm, and whether the circuit connection is normal. By analyzing the images of electronic products, the size, position and shape of solder joints, as well as the relative position and size of various components on the circuit board, can be detected. These test results are crucial to ensuring the quality and reliability of electronic products.

In addition to industrial production, assembly-line intelligent vision inspection systems can also be expanded to other fields. For example, in the food processing industry, such systems can be used to detect characteristics such as appearance, color, size and shape of foods. By processing and analyzing food images, non-conforming products can be discovered and eliminated in a timely manner to ensure food quality and hygiene and safety.

In general, the assembly line intelligent vision inspection system achieves high-precision and high-efficiency product inspection through machine vision technology, effectively ensuring the quality, safety and reliability of products.