scpmkj@gmail.com

Get A Free Quote

Toughened glass can be seen everywhere in daily life. It heats ordinary flat glass to a temperature close to glass softening (600-650 ° C), and multiplies the strength of the glass by rapid cooling or chemical methods, while taking into account thermal stability and Smooth, transparent, and cuttable. Most of the building safety glass uses tempered glass.

However, in order to save costs, many small manufacturers use semi-tempered glass and hot-bent glass, which greatly increases the probability of self-explosion and increases the probability of injury. Especially high-rise architectural glass is more likely to cause damage to people, animals and plants underneath after bursting. Damage, so the quality of tempered glass is very critical. Users are advised to identify tempered glass products with 3C certification marks when purchasing.

3C certification is a kind of safety certification, its full name is the "Compulsory Product Certification System", which is a compulsory certification provided by the country to protect consumers. The 3C certification mark is generally attached to the surface of the product, or pressed on the product through molding, which is a number of elliptical "CCC" symbols, and there is also a random code behind the mark, corresponding to the manufacturer and product. Users can use the national quality certification center to conduct code query and identification.

It should be noted that having a 3C logo does not mean that it is authentic, and the method of pasting the mark will easily become blurred and fall off over time, and the molding method is not suitable for use on glass products. In order to further protect the rights and interests of manufacturers and consumers of tempered glass products, it is a practical and effective way to permanently place the 3C mark on the surface of tempered glass products through laser marking.

In fact, using laser marking to mark tempered glass is not a bizarre thing. On the contrary, due to the broad application range of tempered glass, laser marking and tempered glass products have been deeply bundled. Laser marking can not only easily obtain permanent 3C marks that are not easy to remove, but also provide anti-counterfeiting and traceability functions by marking other graphic information, including logo, QR code, bar code, batch, date and other information.

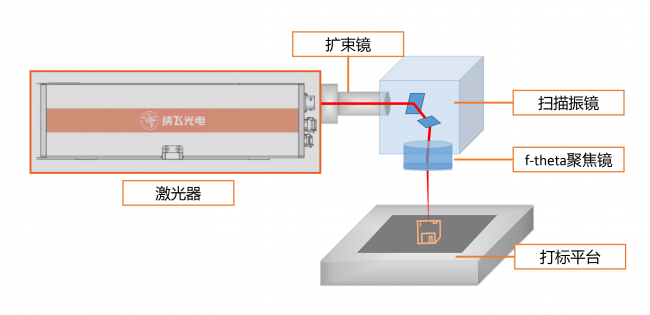

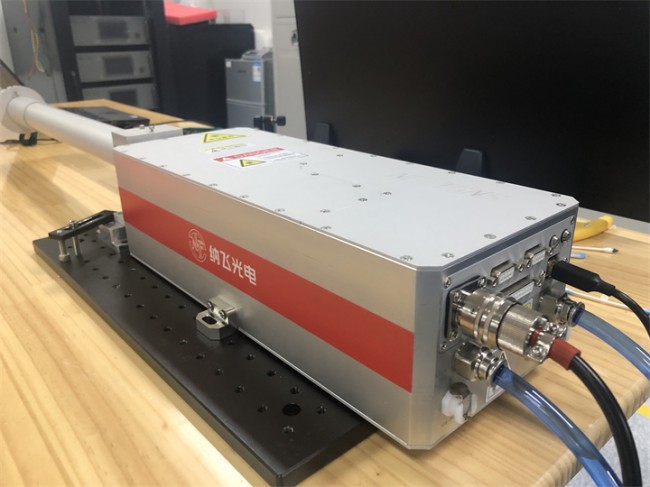

Laser marking is a marking method that uses a high-energy-density laser to locally illuminate a workpiece, causing the surface material to vaporize or undergo a chemical reaction that changes color, thereby leaving a permanent mark. Due to the high light transmission and high hardness of tempered glass, refined marking can be completed by using a nano-photonics 355nm ultraviolet nanosecond laser with narrow pulse width, high material absorption and high beam quality.