scpmkj@gmail.com

Get A Free Quote

What actions do wires and cables do before coding? However, the outer surface of the cables is generally composed of rubber, PVC, PE, PTFE, nylon and other materials. The surface adhesion of these materials is not enough. Usually, the characters sprayed with code can be easily scraped off. Even nails will fall off gently.

In response to this problem, some cable manufacturers have made various attempts, such as replacing high-viscosity inks or using hot-pressed printing labels, but these methods are not a long-term solution, and there are still many problems.

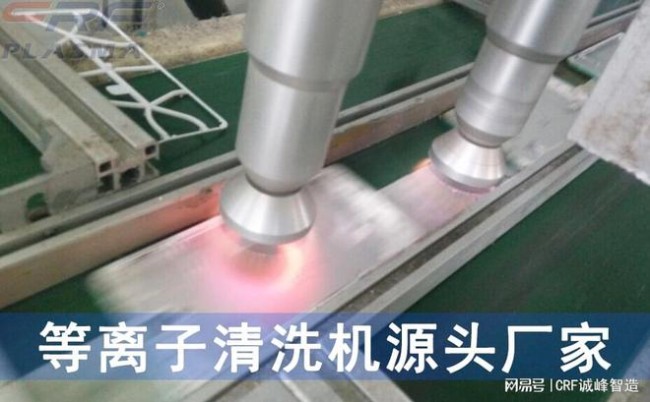

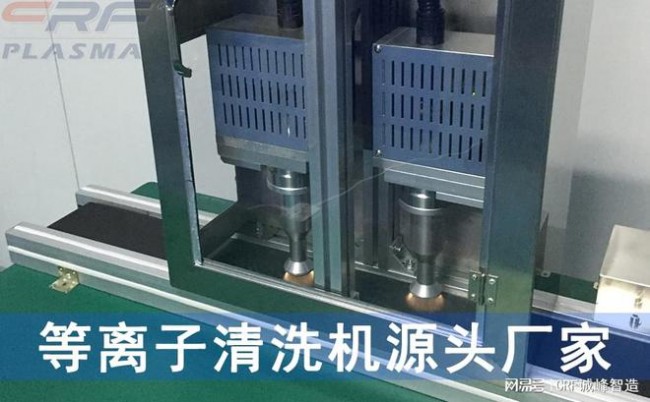

It is said that as long as plasma pretreatment is carried out before spraying the code, the adhesion of the cable surface can be improved. Nowadays, plasma cleaners act on surface pretreatment equipment for various silicone rubber, plastics and other materials, which can improve the surface adhesion of materials. and hydrophilic.

Therefore, when the outer surface of the cable is rubber, after PVC, PE and other materials are bombarded by plasma, the surface activity of the material changes, changing from difficult to easy to adhere, fundamentally solving the problem that the sprayed characters are easy to fall off.

For the production process of cables, plasma treatment can not only effectively prevent inkjet printing from falling off, but can also be completely suitable for assembly line production. Currently, the direct injection nozzle has three processing widths: 3-5mm, 7-13mm, and 15-18mm, which can adapt to the cable diameter. The fastest processing speed can reach 40-50m/min, which can improve the production efficiency of the cable.

Cable cleaning is a commonly used surface treatment method before coding. Use plasma to clean the surface of the cable to remove residues on the surface and improve the adhesion and reliability of cable code coding.

Plasma cleaning can effectively remove organic and inorganic pollutants on the surface of the cable, and can also effectively remove the oxide layer on the surface, providing a clean basis for code printing.

Plasma cleaning is an environmentally friendly and efficient surface treatment method that can not only improve the quality of cable coding, but also extend the service life of the cable. During plasma cleaning, attention should be paid to safe operation to avoid harmful gases and risks of electrification.