scpmkj@gmail.com

Get A Free Quote

The lightweight revolution is coming, and the mini conveyor inkjet printer activates new momentum in small and micro manufacturing

Under the industry trend of the global small character inkjet printer market expected to exceed 5 billion US dollars by 2030, the labeling demand of small and micro manufacturing enterprises is undergoing structural upgrading. The pain points of traditional industrial coding equipment, such as large volume, high cost, and complex operation, are in sharp contradiction with the core demand of small and medium-sized enterprises for "small batch, multi batch, and flexible production". In this context, mini conveyor inkjet printers have emerged, with the core advantages of "integrated design, lightweight operation, and high cost-effectiveness", filling the gap in segmented markets and becoming a must-have tool for industries such as food and beverage, medicine and health, and daily chemical electronics, redefining the identification solution for small and medium-sized production scenarios.

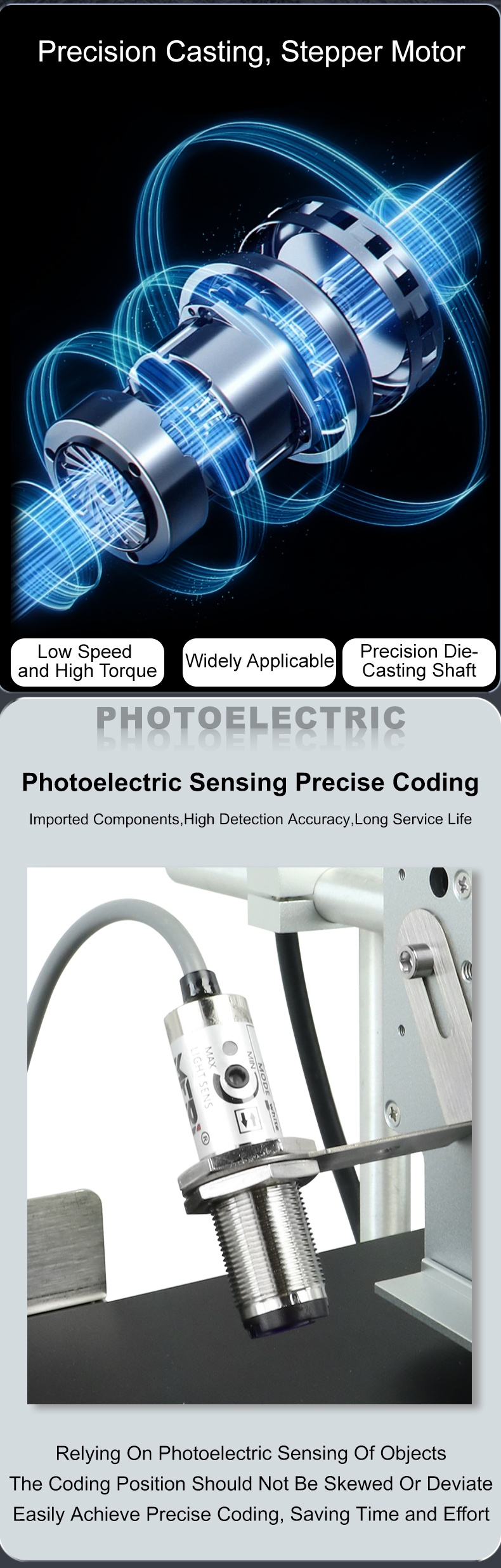

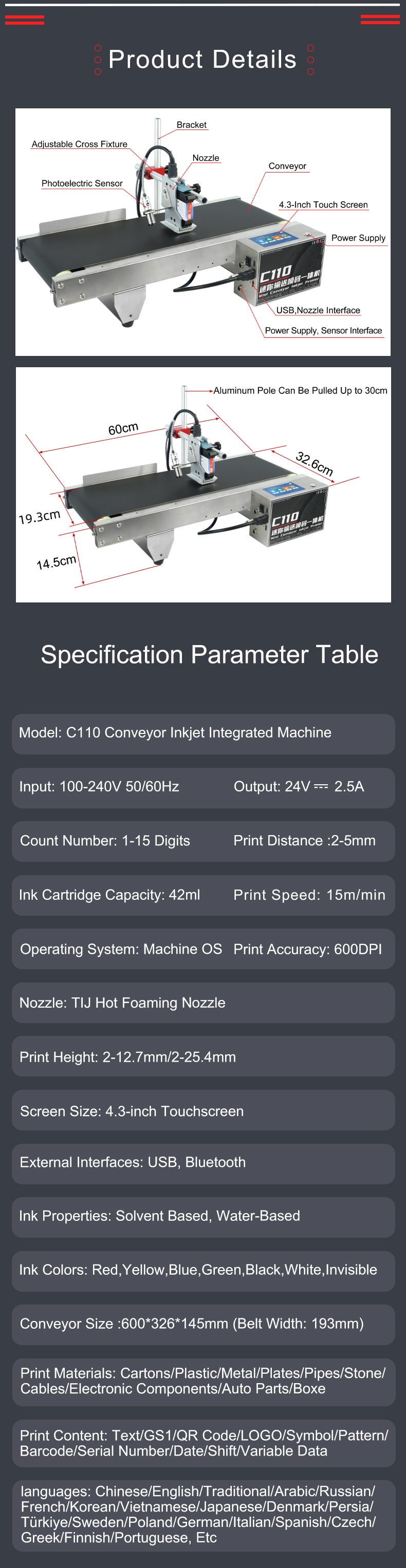

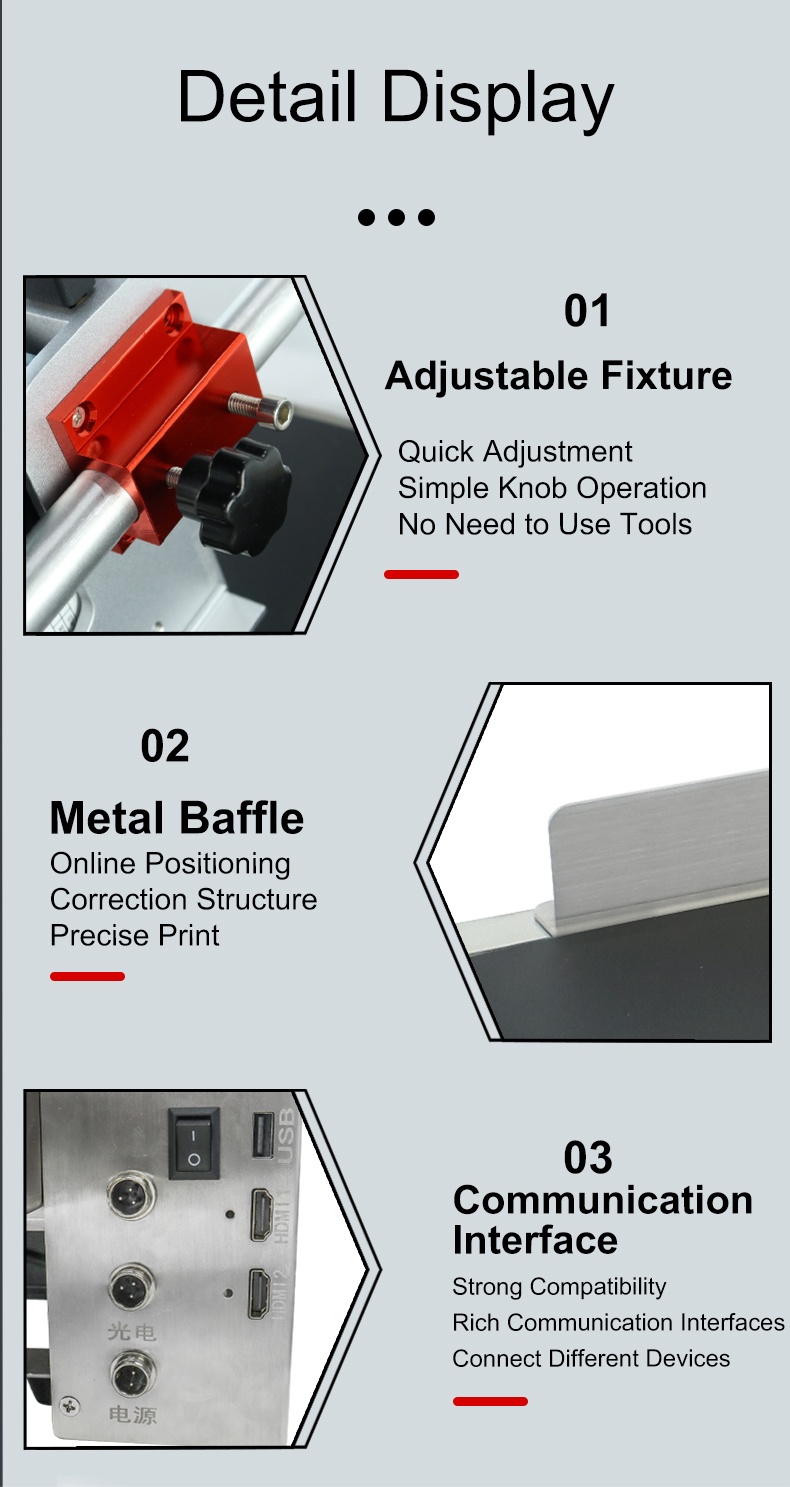

The core breakthrough of the mini conveyor inkjet printer lies in the form innovation of "integration+miniaturization". Unlike traditional equipment that separates conveying and coding functions, this device highly integrates automatic conveying, precise coding, and intelligent detection functions. The body is small and exquisite, and can be easily embedded in limited spaces such as desktops and small assembly lines, completely freeing itself from site constraints. The industrial grade metal body is paired with an upgraded motor to ensure stable operation of the equipment during continuous operation. The high sensitivity and ultra wide touch screen allows for the input and modification of information such as production date, batch number, QR code, and multilingual text in a "what you see is what you get" manner, making it easy for beginners to operate in just 5 minutes without professional training. In response to the demand for multi scenario adaptation, the device supports printing on multiple materials such as plastic, metal, glass, cardboard boxes, woven bags, etc., and can be equipped with optional nozzles of different widths to meet the fine labeling of low-dose drugs and beauty products, as well as long-distance printing of large packaging. It can even meet batch production needs through "one to many" configuration.

Technological iteration enables the mini conveyor inkjet printer to achieve the dual advantages of "small body, high performance". By adopting optimized thermal foaming or CIJ coding technology, the printing resolution of the equipment can reach 600dpi, with clear and sharp characters. Combined with fast drying and anti friction ink, the printing is instantly dried, effectively avoiding problems such as blurring, ghosting, smudging, and falling off. It meets the strict requirements of water washing for food packaging and long-term traceability of medical labels. In terms of intelligent adaptation, some high-end models have achieved deep coupling with MES systems, supporting variable data printing and remote control. Parameter adjustment and data transmission can be completed on the mobile phone, perfectly adapting to the flexible production mode of small and micro manufacturing. What is more noteworthy is that it does not require industrial air compressor drive, consumables replacement is as simple as changing pen refills, standby time is up to 20 hours, and it can respond to sudden orders at any time, completely solving the pain points of traditional equipment being underutilized and maintenance cumbersome.

The precise market positioning enables the mini conveyor inkjet printer to quickly open up growth opportunities. The Asia Pacific region has become the growth core of the global inkjet printer market, and the size of the Chinese market is expected to exceed 1.8 billion US dollars by 2025, with equipment renewal needs from small and medium-sized enterprises accounting for over 40%. These types of enterprises generally face the situation of limited budget and flexible production scenarios. The pricing range of mini conveyor inkjet printers from 499 yuan to 10000 yuan significantly reduces the entry threshold compared to traditional industrial equipment. Users such as Zhejiang Yangmei Cooperative and Guangzhou Handmade Workshop have achieved a significant increase in identification efficiency by three times and a product premium of 15% through this equipment. From the perspective of industry applications, it is widely suitable for production date printing of food and beverages, batch number tracing of medical consumables, serial number identification of electronic products, personalized customization of cultural and creative products, and other scenarios, perfectly meeting the mandatory requirements of product traceability coding at the policy level.

With the penetration of Industry 4.0 into small and medium-sized enterprises, as well as the increasingly strict global product labeling regulations, mini conveyor inkjet printers are facing explosive growth opportunities. It not only fills the market gap of lightweight coding equipment with technological innovation, but also provides a feasible path for the compliance and intelligent transformation of small and micro manufacturing enterprises through the value proposition of "cost reduction, efficiency improvement, and flexible adaptation". In the future, with the deep integration of the Internet of Things and AI recognition technology, mini conveyor inkjet printers will achieve more advanced functions such as automatic material recognition and intelligent parameter adjustment, continuously releasing growth potential in sinking markets and vertical industries, and becoming an important force in promoting the upgrading of China's manufacturing industry segments.