scpmkj@gmail.com

Get A Free Quote

Precision label intelligent printing efficiently empowers color recognition small label pagination coding machine, leading the new revolution of logo automation with heavyweight launch

Against the backdrop of the continuous upgrading of precision, efficiency, and compliance requirements for label identification in industries such as food and medicine, daily chemical beauty, and logistics e-commerce, small label pagination coding equipment has become a core necessity for the digital transformation of production lines. Recently, the leading domestic brand of identification equipment, Shicai, officially launched a new small label pagination coding machine. With the integrated design of "precise pagination+efficient coding+intelligent interconnection", it overcomes the pain points of traditional equipment such as lagging, missing codes, and poor adaptability, providing a full scene identification solution for small and medium-sized production and large-scale assembly line operations, which has attracted high attention from the industry.

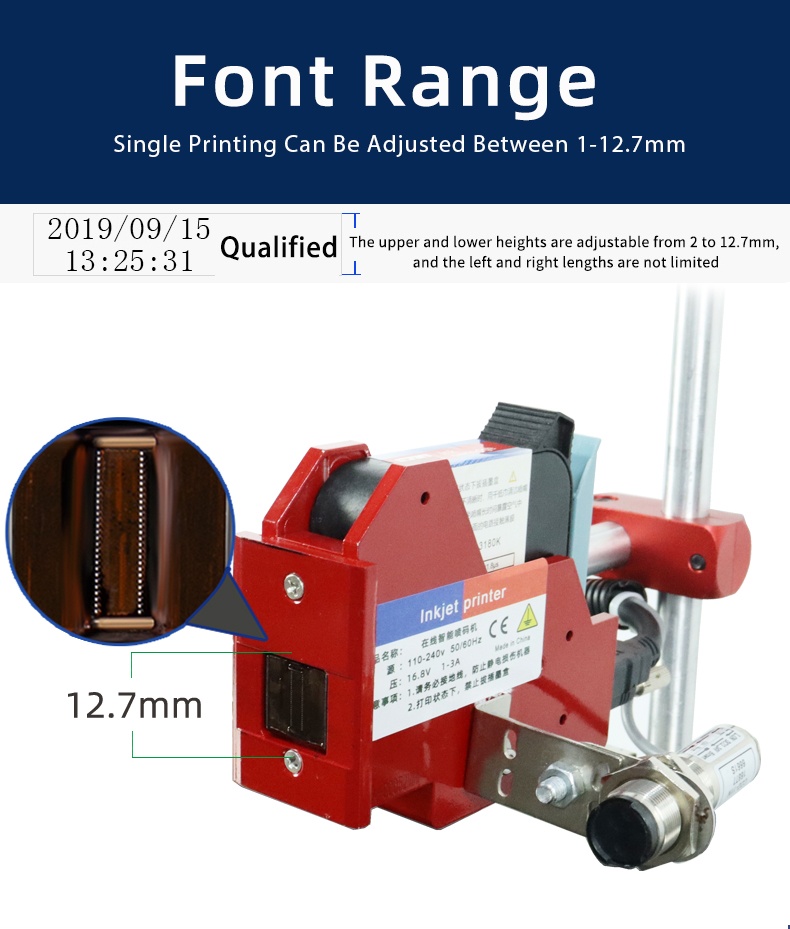

As a star product focused on identifying pain points with small tags, the color recognition small tag pagination coding machine has achieved multiple breakthroughs in core performance. The device is equipped with an intelligent photoelectric sensing pagination system, which adopts a flexible feeding design and can easily adapt to various materials such as A4 paper, kraft paper, adhesive labels, and bill stickers. Even ultra-thin soft labels can achieve seamless separation, with a pagination accuracy of ± 0.2mm, completely eliminating overlapping and misalignment problems. The coding module supports dual mode switching between UV coding and laser engraving, which can accurately print multiple contents such as production date, batch number, traceability QR code, brand logo, etc. The minimum line width of characters is 0.03mm, and it remains clear and does not fall off after high-temperature sterilization, low-temperature freezing, and alcohol wiping tests, fully meeting the strict durability requirements of the food and pharmaceutical industry. Its coding speed is as high as 120 pages per minute, and a single device can replace the daily workload of two manual workers, allowing the traditional mode of processing 8000 pieces per day to be efficiently completed within one hour.

The dual guarantee of compliance and adaptability makes the color recognition small label pagination coding machine widely applicable in the industry. The body is made of food grade 304 stainless steel material, with a smooth and easy to clean surface that meets GMP standards and FDA food contact material certification requirements. There is no harmful substance precipitation during the coding process, making it perfectly suitable for scenarios with high hygiene and safety requirements such as food and medicine. The device supports custom starting numbers and coding digits (0-5 digits optional), compatible with more than 20 operating system languages, and can flexibly match coding rules from different industries. Whether it is shelf life labeling for food packaging, batch number tracing for pharmaceutical products, or single number printing for logistics labels, it can be accurately adapted. At the same time, its modular design supports seamless integration with existing production lines, enabling linkage control and automatic alarm functions to provide real-time alerts in case of abnormal situations such as ink shortage and material jamming, ensuring uninterrupted production.

The deep integration of intelligence and convenience has become the core competitiveness of products. The device is equipped with a high-definition touch screen display, with intuitive and easy to understand parameter settings, and supports switching between Chinese and English. Even beginners can quickly get started with the operation. Built in IoT module, supporting Wi Fi and Bluetooth wireless connections, can achieve real-time data synchronization with enterprise ERP systems and regulatory traceability platforms. Code information can be remotely monitored and batch modified, forming a "production circulation traceability" data loop to meet the compliance requirements of the food and pharmaceutical industry's full chain traceability. According to actual test data verification, after a certain food processing enterprise introduced this equipment, the pass rate of label coding increased from 98% to 99.9%, and labor costs were reduced by 40%; After the application of a cross-border e-commerce platform, the efficiency of package label processing has increased by 300%, and the rework rate for missing codes has decreased by 95%, significantly improving the efficiency of production circulation.

At present, the Chinese paging coding machine market is steadily expanding at a compound annual growth rate of 12%, and the market size is expected to exceed 7.8 billion yuan by 2025. Intelligent automation equipment has become the mainstream demand, and the demand in fields such as food and medicine, logistics and e-commerce continues to be strong. The launch of the color recognition small label pagination coding machine not only precisely meets the market's core demands for efficient, accurate, and compliant labeling equipment, but also relies on the advantages of domestic core technology to achieve independent controllability in key links such as sensor pagination and intelligent control, breaking down the price barrier of imported equipment.

The head of the Shicai brand stated that in the future, they will continue to focus on technological innovation in small label identification scenarios, combining cutting-edge technologies such as AI visual recognition and blockchain traceability to optimize the multi material adaptability and data security of equipment, and provide customized solutions and full lifecycle services for customers in various industries. With the comprehensive launch of the color recognition small label pagination coding machine, it will help more enterprises achieve cost reduction, efficiency improvement, and digital upgrading in the identification process with its core advantages of high cost-effectiveness and high performance, and promote the domestic identification equipment industry to move towards a more accurate, intelligent, and environmentally friendly direction.