scpmkj@gmail.com

Get A Free Quote

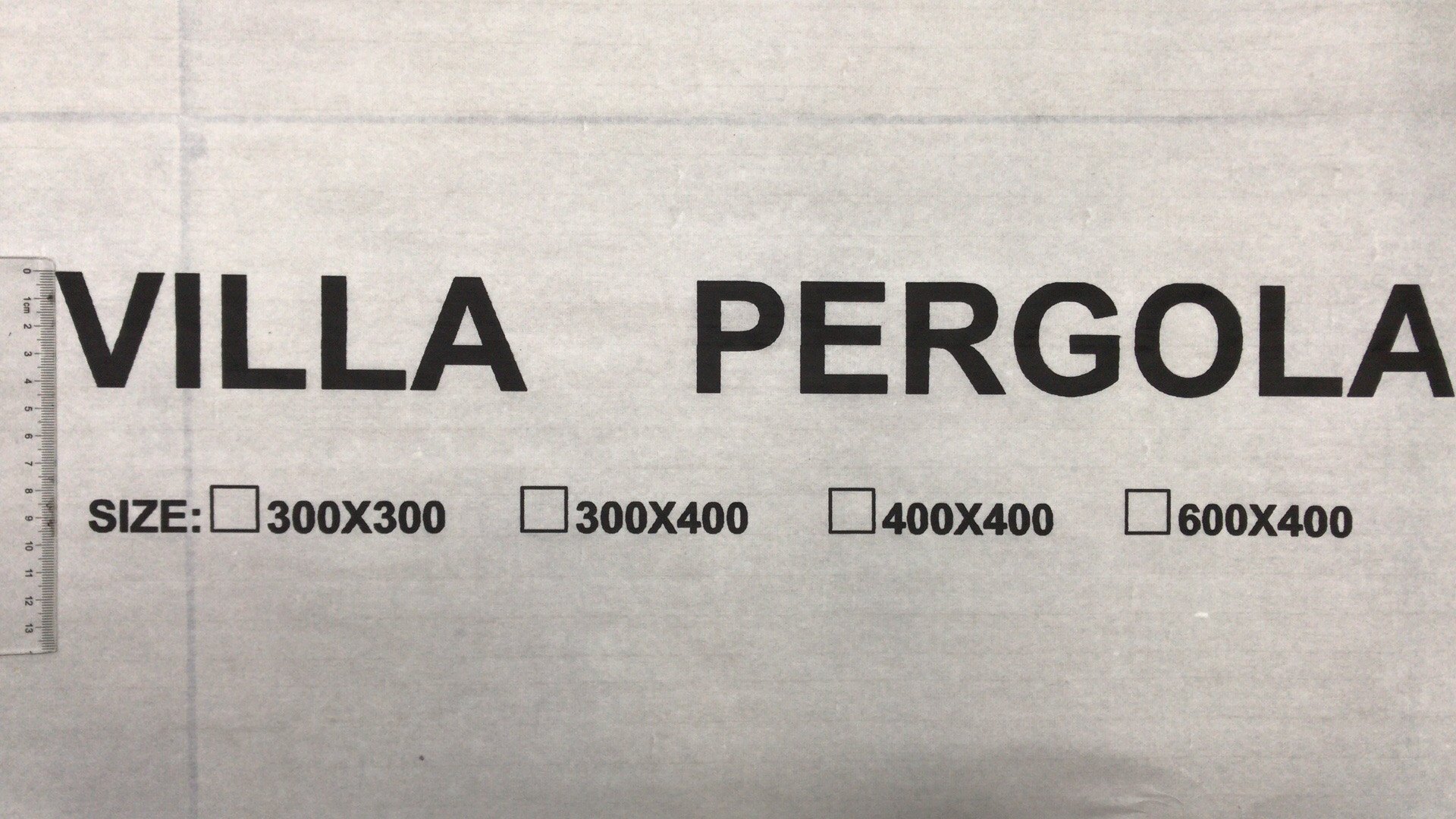

1. Apply high adhesion coding technology to form strong and

wear-resistant markings on rough materials such as woven bags and iron

drums, ensuring that product names, specifications, and other

information are clear and durable during handling and storage, meeting

the outdoor storage and transportation needs of building chemical

products.

2. Adopting anti-corrosion materials and IP65 high protection level

equipment, combined with acid and alkali resistant, UV resistant ink, it

can easily cope with corrosive gas and dust environments in building

chemical workshops, reduce equipment failure rates, and improve usage

stability.

3. Equipped with an IoT intelligent control system, it supports remote

adjustment of coding content and monitoring of equipment status on

mobile apps or PCs, achieving efficient centralized management and fault

warning in large-scale factory areas with multiple production lines.

4. Build a digital traceability system by printing encrypted QR codes or

barcodes, linking information such as raw material batches, production

processes, quality inspection data, etc., to achieve full lifecycle

traceability of products, strengthen quality control and after-sales

response capabilities.