scpmkj@gmail.com

Get A Free Quote

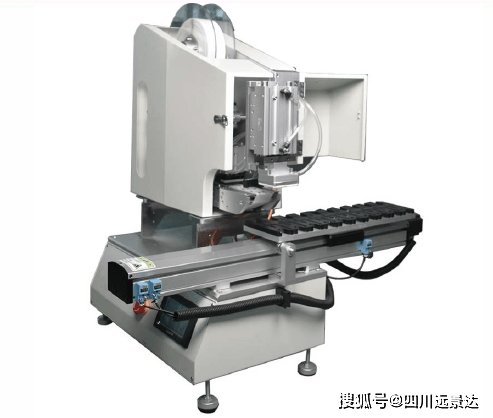

With the increasing demand for unfamiliar products and the continuous reform of mechanized management trends, vegetable labeling is now equipped with professional equipment-vegetable labeling machines. However, such equipment must be operated in accordance with the process, which has a very important impact on whether employees understand the fully automatic vegetable labeling machine. So what methods do vegetable labeling machines need to master during operation and debugging? Let's introduce it to everyone below.

The main difficulties encountered during debugging:

1. It is easy to tear when removing the label, and the label is easy to break. Then check whether the mark is correct. Secondly, check whether the wave plate is pressed too tightly. Another important reason is that the traction frequency is too large, which causes the label to break.

2. When measuring accuracy, the positions on the back and front of the label are different. The measurement accuracy is generally about 3 times per group, and too many labels require too much wave mark plates. At the same time, the traction frequency and transmission frequency are not matched well, and pull marks will appear, causing the label to deviate from the place where it is labeled. You can carefully observe the markings in manual mode to see if the label is incorrect because the wave plate is not adjusted.

3. Wrinkles appear on the label during labeling. During the debugging process, creasing is a common problem. Generally speaking, the traction frequency is too large and the transmission frequency is not large enough. Secondly, it may be the pressure difference of the wave plate. You can try to adjust the parameters repeatedly to confirm whether the traction frequency is too large. Causes the label to wrinkle.