scpmkj@gmail.com

Get A Free Quote

Labeler is a two-in-one system that prints and labels online, which can be simply understood as being printed and pasted immediately. We set up the data content that needs to be printed on the computer and sent it out, then print it out instantly and paste it on the surface of the target product.

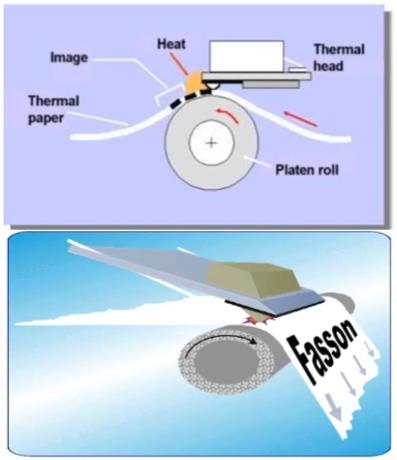

The print head of the Markon Imas labeller is its core component. There is a row of heating resistors on the print head. It is used to heat the ink on the ribbon. After the ink melts, ink dots are formed, and then they are printed on the label. Once the text is printed, you can see with a magnifying glass that the text is composed of countless ink dots. There are two types of printheads: one is 200 DPI, and the other is 300 DPI, which means how many ink dots there are per inch. For example, 200 DPI means 25mm per inch with 200 ink dots on it. 300 DPI means 300 ink dots. The print head uses Flat Edge technology, and the print head life is about 50 kilometers. Relatively speaking, Flat Edge technology has higher print quality and is not easy to damage.

There are two printing methods for the Markon Imas 2200 labeler, one is to use Direct thermal. Commonly known as printing on thermal paper without the need to use a ribbon. The advantages are: easy to use, fast speed, and low cost of using thermal paper (colorless tape). However, there are also relatively shortcomings, such as: printed images are easier to fade, cannot resist heat or UV ultraviolet rays, the label has a short service life, and the color is only black.

The other is to use Thermal Transfer, commonly known as thermal transfer technology. It requires the use of a ribbon and label paper. There is a layer of ink at the bottom of the ribbon. The ink is heated and melted into ink dots, and then printed on the label paper. The advantage of this thermal transfer technology is that it is relatively resistant to environmental impacts, and it can be selected in a variety of colors.