scpmkj@gmail.com

Get A Free Quote

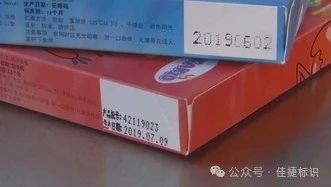

In the code coding industry, we often hear feedback from customers: "Why is code coding always easy to fall off?" "It was obviously high-quality ink, but the color faded!" In fact, the problem may not lie entirely with the inkjet printer or consumables, but a key step is missing-surface pretreatment!

Why does the code fall off?

The adhesion of inkjet printing is affected by many factors, including material, environment, ink type, etc. However, in many cases, the code drops off because there is oil, dust, moisture or other pollutants on the surface of the material, which prevents the ink from adhering firmly.

Key step: surface pre-preparation

processing

Whether it is plastic, metal, glass or other materials, proper surface cleaning and treatment before coding can significantly improve the durability of coding. Here are a few common pretreatment methods:

1. cleaning surface

Alcohol or acetone wipe: Suitable for most materials and can effectively remove grease and stains.

Compressed air dust removal: Suitable for environments with more powder and dust, such as food packaging, building materials, etc.

Special cleaning agent: For special materials (such as PE, PP and other hard-to-adhere materials), special pretreatment agent for code printing can be used.

2. Choose the right ink

Quick-drying inks: Suitable for materials with poor absorption, reducing drying time and reducing the risk of scratching.

High adhesion ink: UV ink or epoxy resin ink can be used for special materials (such as glass, metal).

3. environmental control

Temperature and humidity adjustment: Excessive humidity may cause the ink to dry slowly, while too low temperature may affect adhesion.

Curing after coding: Some inks (such as UV inks) need ultraviolet curing to ensure firm coding.

summary

The shedding of code is not necessarily a problem with the machine or ink, surface pretreatment is the key! If your customers are also complaining that the coding is not strong, check whether the cleaning and material matching are done.